Beginner’s Guide: How Does 3D Printing Work?

Have you ever imagined creating an object from scratch with just a click of a button? 3D printing turns this imagination into reality. It’s a fascinating technology that converts digital models into tangible objects. Traditionally used for prototyping, 3D printing has now expanded into manufacturing, healthcare, and many other industries. This guide will walk you through the basics of 3D printing, its processes, types, and real-world applications to help you understand how this revolutionary technology works.

What is 3D Printing?

Definition of 3D Printing

3D printing, also known as additive manufacturing, is the process of creating three-dimensional objects from a digital file. It works by layering materials like plastic, metal, or resin, one layer at a time, to form a solid object. Unlike traditional methods that remove material from a larger block, 3D printing builds objects from the ground up. This approach enables the creation of intricate designs, complex shapes, and custom pieces, making it a highly attractive option for hobbyists and industries looking to minimize waste.

History of 3D Printing

3D printing dates back to the 1980s when Charles Hull invented the first-ever 3D printing technology, stereolithography (SLA), and patented it in 1986. It revolutionized rapid prototyping for industries like automotive and aerospace. Over time, new methods such as fused deposition modeling (FDM) and selective laser sintering (SLS) were developed, further expanding the technology's potential. Today, 3D printing is used across many industries, including manufacturing, healthcare, fashion, and food production, with new advancements continuously driving its evolution and widening applications.

How Does 3D Printing Work?

The 3D Printing Process Explained

The 3D printing process begins with creating a digital model of the object using computer-aided design (CAD) software, which allows precise control over the object's shape and structure. Afterward, the model is converted into a file format like STL or OBJ that the printer can interpret. Using slicing software, the model is divided into horizontal layers, and the printer follows these instructions to lay down material layer by layer. The process continues until the object is fully formed, with material bonding as it solidifies.

Materials Used in 3D Printing

Various materials are used in 3D printing, each suitable for different applications. Thermoplastics like PLA and ABS are the most common, offering ease of use, durability, and versatility, making them ideal for general and hobbyist use. Metals such as titanium, aluminum, and steel are used for industrial purposes due to their strength and high-performance qualities. Resin, typically used in SLA printers, is ideal for high-precision items like dental models or jewelry. New materials, including carbon fiber composites and edible materials, expand the possibilities even further.

How 3D Printers Create Objects Layer by Layer

3D printing is an additive manufacturing process, meaning the material is added layer by layer. The printer starts by laying down the first layer on the build platform. Each subsequent layer bonds with the one beneath it, creating a solid object from the ground up. The printer’s software directs the movement of the print head or laser to ensure each layer is placed accurately, according to the design. This layer-by-layer technique allows for detailed and complex shapes that traditional methods can't achieve, offering greater design flexibility.

What Are the Different Types of 3D Printers?

Fused Deposition Modeling (FDM) Printers

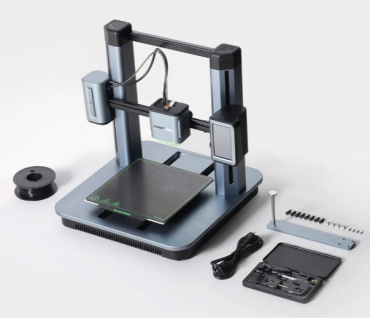

FDM printers are the most common type of 3D printers and are used by both hobbyists and professionals. These printers work by extruding molten thermoplastic through a heated nozzle, which moves along defined paths to form each layer. FDM printers are popular because they are affordable, easy to use, and can work with a wide variety of materials, including PLA, ABS, and PETG. They are ideal for producing prototypes, educational models, and low-cost consumer products.

Stereolithography (SLA) Printers

SLA printers offer high precision and smooth surface finishes, making them ideal for applications that require fine details. These printers use a UV laser to cure a liquid resin, solidifying it layer by layer to create a 3D object. SLA printers are often used in industries such as jewelry, dentistry, and engineering, where high accuracy is critical. Because of the smoothness of the finished product, SLA prints often require little post-processing, which saves time compared to other methods.

Selective Laser Sintering (SLS) Printers

SLS printers use a laser to sinter powdered materials such as nylon, metals, and ceramics, fusing the particles together to form a solid object. SLS is known for its ability to create durable, complex geometries that would be difficult to achieve with other 3D printing methods. This technology is commonly used for industrial applications, including the production of functional prototypes and end-use parts. The ability to work with metal powders makes SLS particularly useful in the aerospace and automotive industries.

What Are the Applications of 3D Printing?

3D Printing in Manufacturing

In manufacturing, 3D printing is transforming the way products are designed and produced. It allows manufacturers to quickly prototype new designs, which reduces the time and costs involved in product development. The ability to make custom parts on demand is especially beneficial for small-batch production, minimizing waste and excess inventory. As a result, 3D printing has revolutionized industries like automotive, aerospace, and consumer electronics by enabling more flexible and cost-effective manufacturing processes.

3D Printing in Healthcare

3D printing is making a significant impact on healthcare by allowing for the creation of custom implants, prosthetics, and medical devices. Surgeons use patient-specific 3D models to plan surgeries and create tailored solutions that improve patient outcomes. Additionally, advances in 3D bioprinting hold the potential to print tissues and organs, which could lead to groundbreaking advancements in regenerative medicine and organ transplants. The ability to produce personalized medical solutions has the potential to improve the quality of healthcare worldwide greatly.

3D Printing in Education and Research

In education, 3D printing is being used to enhance learning experiences and foster creativity. Students in fields such as engineering, architecture, and design can use 3D printers to bring their ideas to life, making it easier to visualize concepts and create physical prototypes. In research, 3D printing is a valuable tool for experimenting with new materials, creating custom laboratory equipment, and developing innovative technologies. The accessibility and versatility of 3D printing are helping to spark new ideas and drive innovation across many fields.

Conclusion

3D printing is a groundbreaking technology that continues to shape the future of manufacturing, healthcare, education, and many other industries. From its humble beginnings in the 1980s to its widespread use today, 3D printing has proven to be an invaluable tool for creating custom objects with complex geometries. Whether for prototyping, production, or medical applications, 3D printing has the potential to revolutionize how we design, create, and manufacture products. If you’re new to 3D printing and looking for a good starting point, finding the best starter 3d printer can help you dive into this technology. Understanding its basic principles and applications is the first step toward exploring its vast potential.

![PAU - [ Altern@tives-P@loises ] PAU - [ Altern@tives-P@loises ]](http://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/179/2022-3-2/21584.jpeg)

![Good deal: 15% bonus credit on App Store cards of €25 and more [completed] 🆕 | iGeneration Good deal: 15% bonus credit on App Store cards of €25 and more [completed] 🆕 | iGeneration](http://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/179/2022-3-2/21870.jpeg)

Related Articles